TI DLP991UUV Pushes Lithography Into Sub-Micron Precision

TI DLP991UUV Pushes Lithography Into Sub-Micron Precision

The Next Leap in Lithography

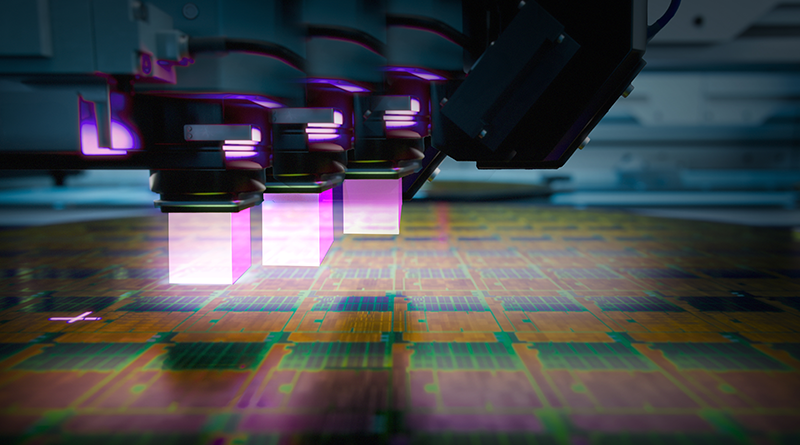

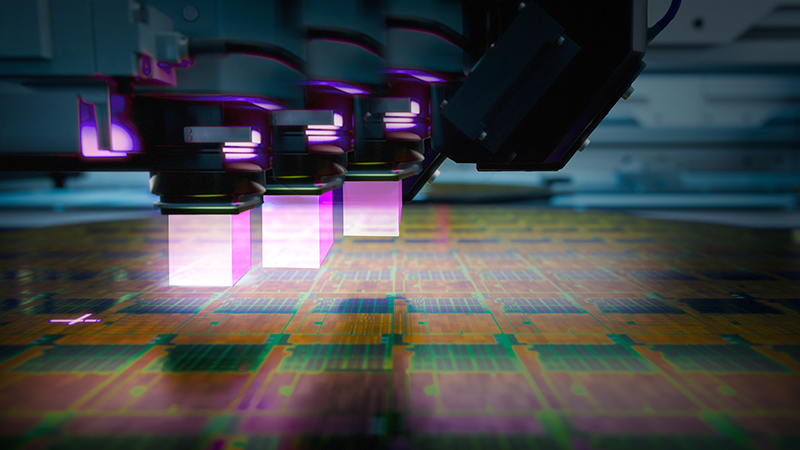

Texas Instruments has unveiled the DLP991UUV digital micromirror device (DMD), and it’s not just another incremental update—it’s a leap. With 8.9 million pixels, sub-micron resolution, and a blistering 110 gigapixels per second data rate, this device is designed to push the boundaries of maskless digital lithography. TI DLP991UUV Pushes Lithography Into Sub-Micron Precision

For context, lithography is the process of etching circuit designs onto substrates. Traditionally, this required expensive masks—physical stencils that had to be manufactured, maintained, and replaced. TI’s new DMD eliminates that need. Instead, it acts as a programmable photomask, projecting light patterns directly onto materials with pixel-level precision.

That’s not just clever engineering. It’s a cost-saving, time-saving, and yield-improving revolution.

Why Maskless Matters

Maskless digital lithography is gaining traction because it solves a fundamental bottleneck in semiconductor and packaging manufacturing. Every time a design changes, a new mask has to be created. That’s expensive and slow.

With TI’s DLP technology, manufacturers can make real-time design adjustments without waiting for new masks. Imagine being able to tweak a circuit layout on the fly, then immediately project it onto a wafer. That’s agility at a scale the industry has been craving.

And let’s not forget the applications. Advanced packaging—where multiple chips and technologies are combined into a single package—is critical for data centers, AI systems, and 5G networks. These systems demand components that are smaller, faster, and more power-efficient. TI’s DLP991UUV is built to deliver exactly that.

Hardware That Means Business

The DLP991UUV isn’t just about resolution. It’s about precision engineering.

- Resolution: 8.9 million micromirrors, each just 5.4 microns in pitch—the smallest in TI’s portfolio.

- Speed: A staggering 110 gigapixels per second, ensuring throughput keeps up with industrial-scale demands.

- Wavelengths: Operates at 343nm to 405nm, making it versatile for different lithography processes.

- Power: Delivers 22.5 W/cm² at 405nm, enough to handle demanding substrates.

This combination means manufacturers can achieve sub-micron accuracy on substrates of virtually any size. The result? Higher throughput, fewer defects, and improved yields.

Image Control at the Pixel Level

What makes the DLP991UUV unique is its ability to act as a programmable photomask. Each micromirror can tilt thousands of times per second, directing light with surgical precision.

This isn’t just about drawing lines on silicon. It’s about controlling light in ways that allow for complex, multi-layered designs. For advanced packaging, where chips are stacked and interconnected in increasingly intricate ways, that level of control is invaluable.

And because it’s digital, corrections can be made in real time. No more waiting for a new mask to arrive. No more production delays. Just instant adaptability.

My Take: Why This Excites Me

I’ve covered enough semiconductor launches to know that not every “breakthrough” is truly groundbreaking. But this one feels different.

The DLP991UUV isn’t just a spec bump—it’s a rethink of how lithography can be done. By removing the dependency on masks, TI is giving manufacturers flexibility they’ve never had before. And in an industry where time-to-market can make or break billion-dollar products, that flexibility is priceless.

For readers, the benefit might feel abstract at first. After all, most of us aren’t running lithography machines in our garage. But here’s the connection: the chips that power your smartphone, laptop, 5G router, or AI assistant all rely on advanced packaging. The faster and more efficiently those chips can be manufactured, the faster you get access to more powerful, more energy-efficient devices.

And yes, it also means fewer delays when the next big gadget is announced.

From Cinema to Circuits

Jeff Marsh, TI’s VP and GM of DLP technology, put it best: “Just as we redefined cinema by enabling the transition from film to digital projection, TI’s DLP technology is once again at the forefront of a major industry shift.”

It’s a fitting analogy. DLP technology first made its mark in digital projectors, replacing reels of film with millions of tiny mirrors. Now, those same mirrors are being used to etch circuits at the nanoscale. From movie theaters to microchips—that’s quite the career shift.

Cost, Scale, and Yield

Let’s talk economics. Semiconductor manufacturing is brutally expensive. Masks alone can cost hundreds of thousands of dollars per design iteration. By eliminating masks, TI’s DLP technology slashes those costs.

But it’s not just about saving money. It’s about scalability. The DLP991UUV can handle substrates of varying sizes, making it adaptable to different production lines. And because it reduces defects, it improves yield—the percentage of usable chips per batch.

Higher yield means fewer wasted wafers, which translates to lower costs and faster production cycles. For manufacturers, that’s the holy trinity: cheaper, faster, better.

The Bigger Picture: AI and 5G

Why does this matter now? Because the demand for high-bandwidth, low-power components is exploding. AI systems need chips that can crunch data without overheating. 5G networks need hardware that can handle massive traffic without guzzling power.

Advanced packaging is the answer, and lithography is the bottleneck. TI’s DLP991UUV is designed to remove that bottleneck, enabling the next generation of computing.

In other words, the future of AI and 5G might just hinge on millions of tiny mirrors tilting at the speed of light.

Availability and What’s Next

Preproduction quantities of the DLP991UUV are already available on TI.com, with multiple payment and shipping options. That means equipment manufacturers can start integrating this technology into their systems today.

And let’s be real: once this tech scales, we’ll see ripple effects across the entire electronics industry. Faster chip production. More efficient devices. And maybe, just maybe, fewer headlines about global chip shortages.